Case Study

Offline-First Management System for Machine Tools

Offline-First Machine Tool Management System

In large industrial machine shops and factories, with tools like lathes, drill presses and automated CNC machines, you can’t simply take a piece of metal, clamp it in a vise or chuck and start removing material: it’s vitally important that the tool and the workpiece are cooled properly. If they heat up, the cutting implements wear out and break, and the workpieces turn out inconsistent. Every type of machine, material and process may require specialised cooling fluids, and since these accumulate metal shavings and other dirt, they must also be continually monitored and topped up, re-mixed or replaced as needed. This is quite a bit of organisational overhead, and it has to be done in noisy, dirty and frequently offline places.

The Brief: Our client needed to digitise regular analysis of cooling fluids used by machine tools in industrial workshops and factories. The goal is to keep each set of fluids in each machine within specific limits, which in turn depends on the machine type, the fluids used, the workpiece material, the type of machining process used and various other factors.

The old measurement process was entirely paper-based until the last step, where the data was manually input into spreadsheets. As such the process offered several points of friction and opportunities for introducing errors. The client either sent people around the country to perform these measurements at their customers’ shops, or larger customers would be trained and submit their data to the client application in their own time.

Challenges: It turns out that machine shops are fully offline in a surprising number of cases, either because they’re in basements or all-metal buildings that are effectively Faraday cages with no cell reception. Many places have no local wi-fi, or if they did, getting access to it was difficult. As such, the app needed to be Offline-Capable: machine inventories and limited measurement histories should be available on-device, and taking new measurements, adding notes, photos and even entirely new machines should be possible without a network connection. The generation of report PDFs should also be possible on-device.

Our Solution: We built a progressive web app based on React and PouchDB, with a Node.js/CouchDB backend, and also operate the production environment. The app offers:

- Almost complete offline capability: all functions except user administration are fully available without network access: once they’ve pre-loaded the customer data onto their devices, field staff are completely independent of network infrastructure and can perform their tasks hassle-free with no lag. The data automatically syncs from their devices once the network becomes available again later.

- Client-side data graphing, inventory searches, measurement history per machine and facility, PDF generation, task management and delegation, QR code reading and generation for machine labels, and deferred email sending.

- Flexible machine setups, with multiple different measurement points per machine and multiple measurement types possible per measurement point, and custom validation rules per point.

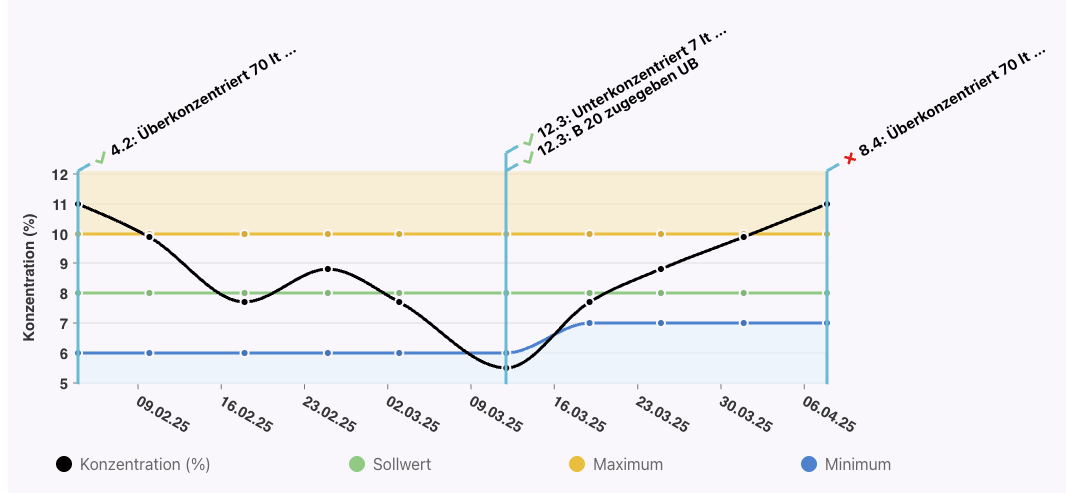

- In-app warnings and email notifications to field staff and/or supervisors if measurements fall outside of expected limits.

- Complex multi-tier customer and user management with role-based access control, and with customers being able to re-sell the app to their own customers.

- Different pre-loaded local data sets per-user, depending on context and role.

The Result: The app has been running in production since 2020, with over a hundred customer accounts and many hundreds of machines. Measurement and maintenance processes have been both simplified and expanded, are faster and more robust, and offer far fewer opportunities for users to introduce errors into the data. Measurements are validated on input, and field staff can immediately look up each machine’s measurement and maintenance history on-site, regardless of whether they have an internet connection or not. Machines can also be looked up much more easily by entering a short unique ID or scanning their QR-code labels. Longer-term data analysis is built in and no longer requires field staff to maintain spreadsheets and build their own graphs.

Custom graph showing the concentration of a specific chemical in relation to its desired minimum and maximum limits over time, using on-device data. The vertical lines show work orders and notes.